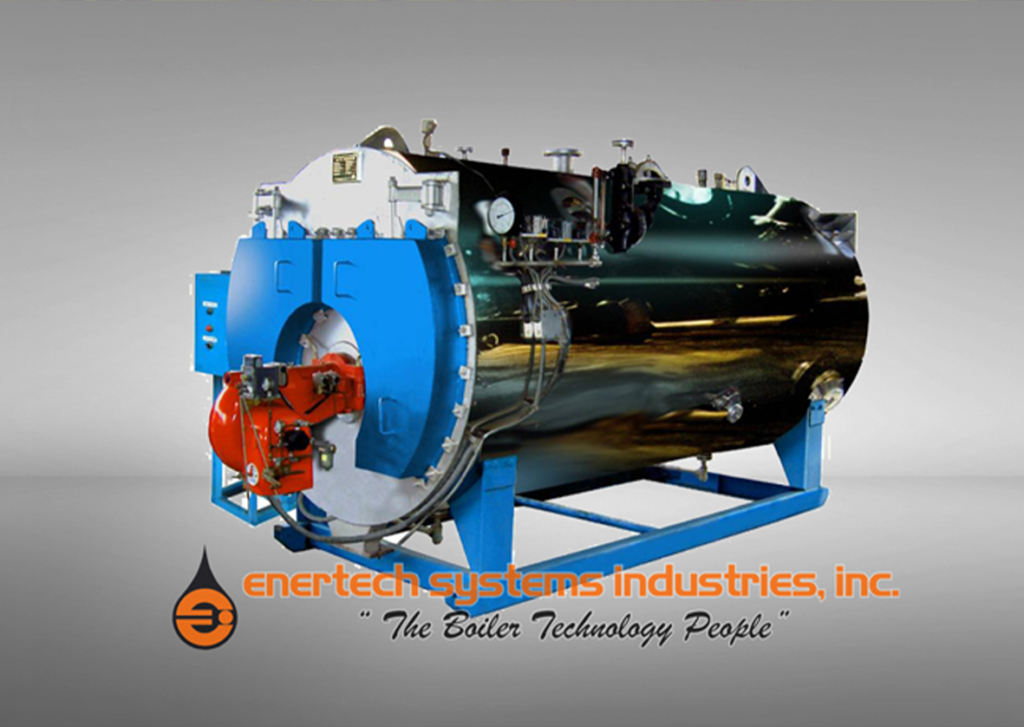

ANZEN BOILER

The ANZEN Boiler is an economically priced model available in capacities from 20-1500 HP (300-23,500kg/hr.) with a standard design pressure of 150 PSIG; also available for design pressures of up to 300 PSIG. The ruggedly-built unit is fully automatic and has been proven in the field to be very reliable. ANZEN Boiler is equipped with a simple but well designed pressure atomized burner, with models for light oil, heavy oil and gas firing.

ANZEN BOILERS

TECHNICAL SPECIFICATIONS

| TYPE: | 2 PASS DRYBACK AND

3 PASS WETBACK PACKAGED FIRETUBE STEAM BOILER |

| NOMINAL CAPACITY: | 20 TO 1500 HP |

| STEAM CAPACITY: | 300 To 23,500 KG/HR |

| DESIGN PRESSURE: | 150 TO 300 PSIG |

| BOILER FUEL: | DIESEL, LSFO, LSP OR BUNKER C |

| CONTROLS: | FULLY AUTOMATED:

BOILER AUTOMATION SYSTEM (BRAIN ++) |

| COMPLIANCE: | DOLE/DENR |

| THERMAL EFFICIENCY

(STANDARD) | 85.1%(ABMA/ASME): 92.2% (EURO/TUV) |

| DESIGN REFERENCE CODE: | PSME/ASME |

CONSTRUCTION FEATURES:

- Davited front doors and split/hinged rear doors allow access to return tubes for ease in cleaning and maintenance.

- Front and rear doors are held shut using studs with lugs and brass nuts for easy removal.

- Front smoke box and doors are lined with space-age ceramic fiber.

- Large furnace – large diameter and sufficient length, provides required furnace volume assuring complete combustion of fuel, especially heavy oil. Furnaces are of ring-reinforced type providing a very rigid structure and at the same time additional heating surface from the stiffener rings.

- Wet-back design turnaround eliminates the need for refractory lining, baffles, gaskets and provides additional primary heating surface for increased efficiency.

- Two inch thick 132 kg/cu cm density mineral wool insulation reduces heat loss through the shell surfaces.

- Round smoke outlet requires only a stub stack for proper draft.

Stainless steel finish for shell, to provide aesthetics and durability - Capacities from 20 to 1500 Bo. HP (300 to 23,500 kg/h).

- Operating Pressure of up to 300 psig .

- High efficiency, attaining thermal efficiency of up to 93% at MCR when firing heavy oil (based on LHV) 3 pass wet-back design combined with a generous heating surface of 5 sq/ft per BoHP. Wet back design eliminates heavy refractory at rear door reducing maintenance cost.

- Highly efficient full modulation U.S. made Industrial Combustion Burner, air/steam atomized burner with 5:1 turn down, attains very high combustion efficiencies even at low loads.

- Large heating surface and high efficiency burner, translates into large savings in fuel cost High quality fittings and components